Hyosung pharmtech’s uphill type deduster allows dedusting and deburring any type of tablets.

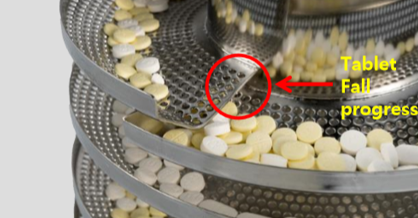

Stepless vibration creates a vertical ascension of the products.

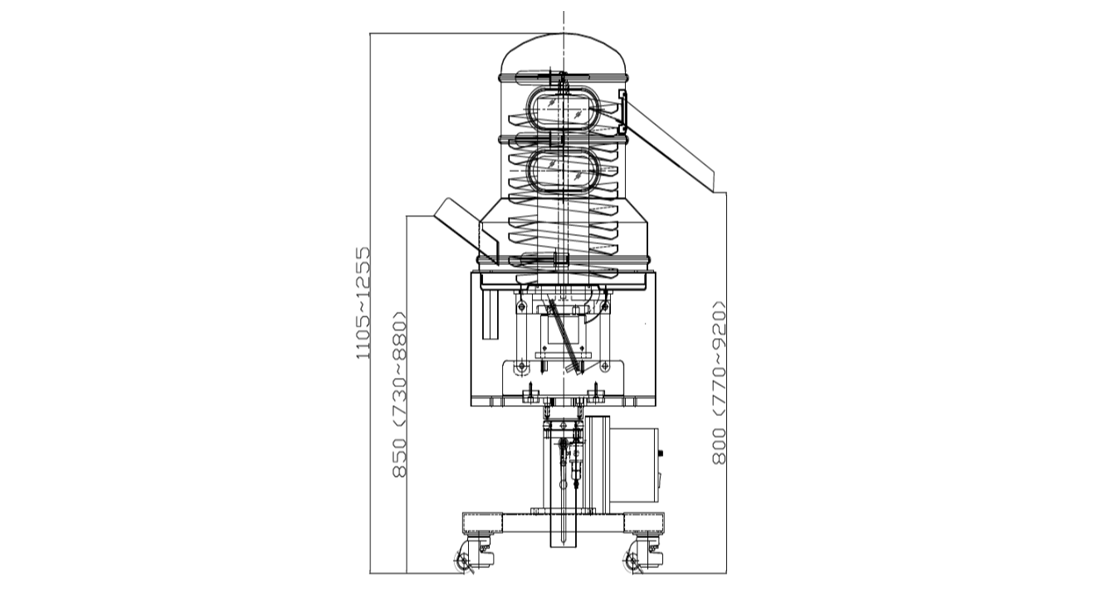

The deduster’s inlet height can very between 715mm and 865mm in direct relation with the outlet height required.

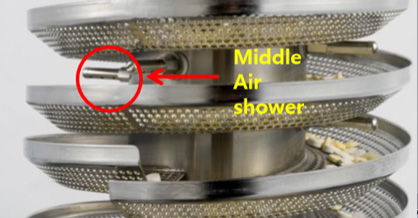

The spiral enabling ascending movement of the tablets has been achieved in 316L steel with continuous TIG welding.

The equipment uses a new principle of dust extraction, immediately separating any powder excess during the dedusting process. At the concept, an utmost care has be en taken concerning the noise level as well as achievenment following highest GMP standards.

The clean-up is easy, not requiring any tooling equipments are available in mirror finished.

An optional two ways diverter allows you to switch from one bin to the other without operator’s Action.

Features

| Model No. | HSD900 |

|---|---|

| Inlet height (A) | 715-865mm |

| Outlet height (B) | 779mm-920mm |

| Floor dimensions (CxD) | 460 x 500mm |

| Inlet chute dimensions | 115 x 40mm |

| Minimum tablets size | Ø4mm |

| Maximum tablets size | Ø25mm |

Dedusting/deburring distance |

6.3m |

| Noise level (Db) | Max. 72 Db |

| Input power | 220VAC, 1P, 50/60Hz |

| Brutto weight | 135kg |

| Capacity/Speed exemples: | |

| Round tablets Ø5mm | 1 200 000 tabs/H |

| Round tablets Ø8mm | 1 000 000 tabs/H |

| RoundtabletsØ13mm | 850 000 tabs/H |

| shaped tablets 8x4mm | 850 000 tabs/H |

| shaped tablets 19x7mm | 600 000 tabs/H |