Hyosung pharmtech’s “HSM1200”allows uphill type dedusting and deburring of any type of tablets.

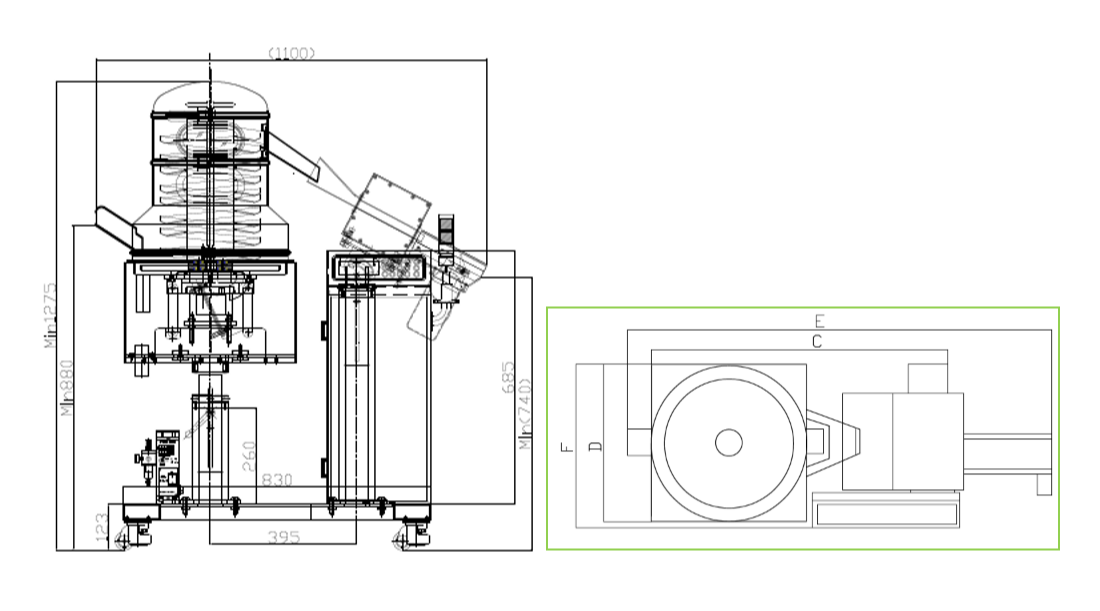

Stepless vibration creates a vertical ascension of the products. The deduster’s inlet height can vary between 770 mm and 855 mm in direct relation with the outlet height required.

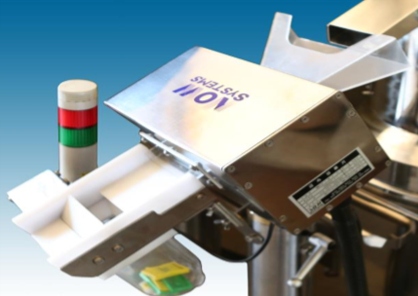

The “HSM1200”dedusters are equipped with a metal particles detector. As metal particles detectors are very sensitive to vibrations, the vibrating parts of the dedusters are isolated from the steady parts of the frame.

This permits reaching an optimal accuracy such as a spherical stainless steel part of 0,5 mm in the products. A high speed rejection mechanism instantly rejects non conform products.

The construction of this special frame saves space into the production room and reduces the retention areas. In addition, the circuit of tablets is therefore totally closed between the inlet into the deduster and the outlet of the metal particles detector.

www

Features

| Head size | Accuracy Ferrous | Accuracy Non-Ferrous | Accuracy STS 316L |

|---|---|---|---|

| 95 x 38mm | 0.3mm | 0.35mm | 0.5mm |

| Technical data: | HSM 1800 | |

|---|---|---|

| Inlet height (A) | 1090 ~ 1175mm | |

| Outlet height (B) | 800mm-885mm | |

| Floor dimensions (CxD) | 770mm x 460mm | |

| Capacity | Round tablets ø6mm | 1,200,000 tabs/H |

| Round tablets ø8mm | 1,000,000 tabs/H | |

| Round tablets ø13mm | 850,000 tabs/H | |

| Shaped tablets 8x4mm | 850,000 tabs/H | |

| Shaped tablets 19x7mm | 600,000 tabs/H | |

| Noise level | 72 Db | |

| Electrical power | 220VAC, 1Phase, 50/60Hz |

|

| Weight | Approx. 220kg | |